Zhejiang Chuangkai Mechanical and Electrical Technology Co., Ltd. was established in March 2003, with a registered capital of 15 million RMB. The company is a high-tech enterprise integrating the design and manufacturing of precision molds, precision metal stamping, precision sheet metal processing, precision machining, surface painting, baking, spraying, and assembly of precision components.Currently, it has 95 employees and possesses advanced precision processing equipment and standardized workshops, with a total area of approximately 13,500 square meters. We have obtained ISO9001, ISO45001, and ISO14001 system certifications. In 2025, we plan to complete the IATF16949 certification.

about chuangkai

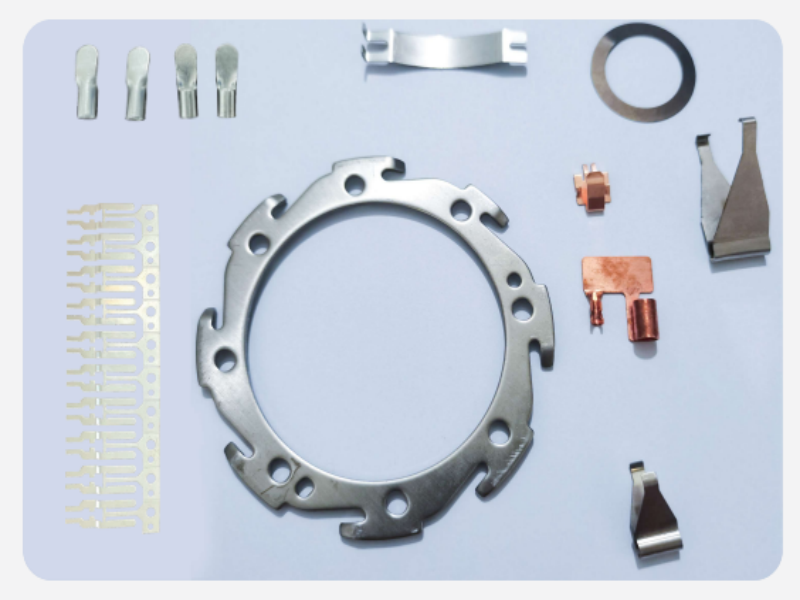

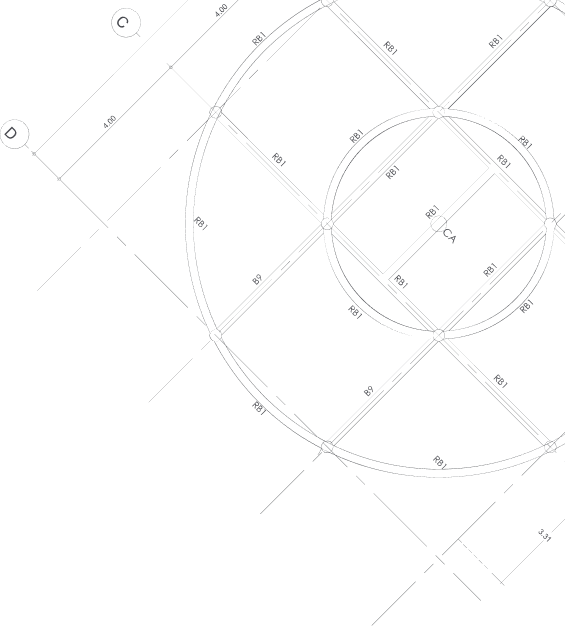

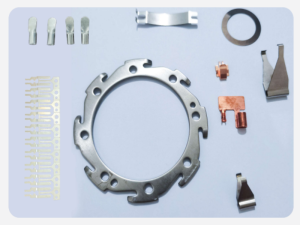

Precision stamping tooling design & manufacture

Main stamping equipment in the stamping workshop: 13 sets of high-speed precision punch presses with specifications such as 16 tons, 25 tons, 40 tons, 60 tons, 80 tons, 110 tons, and 200 tons. The speed of the precision high-speed punch press can reach 500 times per minute.

Materials for stamping processing: brass, phosphor bronze, beryllium bronze, nickel white copper, as well as various types of steel and stainless steel materials, Ni strips, cold-rolled steel, strip steel (including pre-plated), galvanized sheets, low-carbon steel, spring steel, and other composite materials.

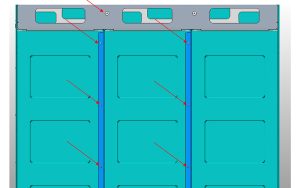

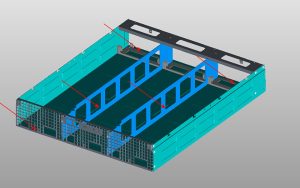

Precision sheet metal manufacture

The sheet metal workshop is equipped with precision sheet metal processing equipment, including 2 large-scale advanced CNC laser cutting machines, 1 CNC punch press, 5 CNC bending machines, as well as riveting machines, welding machines, grinders, wire drawing machines and other equipment.

The processed products cover industrial automation, medical equipment, electrical equipment, electrical boxes, electrical junction boxes and other fields. It can perform precision processing such as rapid cutting and sheet metal processing on the following metal materials: stainless steel, carbon steel, silicon steel, aluminum alloy, galvanized sheet, aluminum-zinc plated sheet, etc.

Powder Coating & Painting

One automatic powder coating line;

One manual powder coating line (for large parts and large boxes);

One manual painting line (for large parts and large boxes);

One automatic powder coating and painting hybrid line under construction.

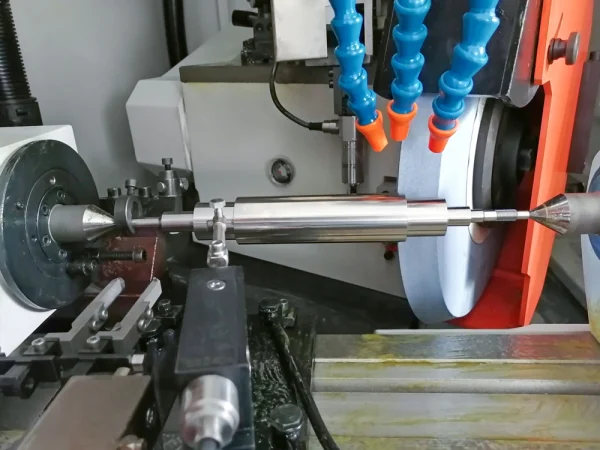

Precision machining

The machining workshop is equipped with precision equipment, including 6 sets of 4-axis CNC machines, 1 set of 5-axis swiss-type lathe, 13 sets of precision CNC lathes, 4 sets of CNC milling machines, 16 sets of Taiwan Mingyang precision automatic lathes, as well as precision ordinary lathes, precision 3-axis digital display milling machines, precision bench lathes, Taiwan Jizuan automatic edge milling machines, precision thread rolling machines, thread rolling dies, precision tapping machines, precision drilling machines, precision Taiwan digital display milling machines, precision knife grinders, internal and external cylindrical grinders, centerless grinders, sawing machines, ultrasonic cleaning and drying machines, polishing machines, electric welders, arc welders and other equipment.

our

Achievement

our fun facts

No more coordinating 5 + suppliers. Cost - Smart Production : Vertical integration + process optimization = 15 - 30% cost reduction vs. fragmented supply chains.

Speed-to-Market:Concurrent engineering cuts lead times by 40%. Meet deadlines without compromising quality.

Request a Free DFM Analysis:Upload your drawings/samples. Our engineers will identify cost & efficiency optimizations within 48 hours.

the company is built

0

registered capital

0M

staff

0+

factory area

0+

our case

Use Stretching process Substitute for Weld+Polish +Scrape putty Technology

Use Stretching process Substitute for Weld+Polish +Scrape putty Technology

Break through the technical bottleneck and create high-quality and price-price metal structural parts for teaching demonstration equipment:

When a customer was developing a large demonstration computer for training and teaching, its core metal structural parts encountered serious challenges. The initial design of the part uses the welding process to make the protruding part, but in the product testing stage, the poor welding tightness makes the product unable to pass the key test. At the same time, the high cost of the welding process makes the price of the parts significantly higher than that of competitors, the project delivery is imminent, and customers face great pressure of quality and cost.

Accurately locate pain points and respond quickly to tackle them:

After understanding the customer’s plight, we quickly set up a special technical team. In the first technical seminar, we deeply analyzed the root cause of poor welding airtightness. Although by optimizing welding parameters and introducing welding machinesPeople, we have successfully solved the problem of airtightness and met the initial quality requirements of customers, but the problem of high welding cost is still pending.

Innovative plan, two-proged:

The technical team didn’t stop there. After many rounds of internal discussion and close communication with customers, we have proposed a fundamental solution: replace the original welding with an integrated stamping and stretching process.+Polish+Scrape putty Craft. This not only completely eliminates the risk of welding tightness from the source, but also significantly reduces the production cost and provides the possibility for the product to win a larger market space.

Seize”Impossible”, fulfill the promise:

Customer feedback has considered stamping.StretchingThe plan, but other suppliers said it could not be realized. In the face of questioning, we firmly believe that”One learns by doing”. Based on the profound accumulation of technology, we provide customers with key optimization suggestions, including:

Adjust the tensile slope angle to optimize the material fluidity, and choose a specific brand of cold-rolled steel plate with better tensile performance.

Excellent results, praised by customers:

After the plan was determined, we conducted multiple rounds of rigorous process tests and sample verification. The final delivered parts perfectly meet the customer’s design requirements and performance standards. The customer was extremely satisfied with the results, and not only gave high praise:”This is the perfect product in my ideal design!”He also expressed his sincere thanks for the ability of the Chuangkai team to overcome difficult problems. We have successfully helped customers within the urgent delivery period, while solving difficult quality and cost problems, and helping their products gain an advantage in market competition.

OvercomiNg Technical Hurdles to Deliver High-Quality, Cost-Effective Metal Components for Educational Displa And Systems

The challenge:

A client developing large demonstration computers for training and education faced Critical iss Ues with a key metal structural component. The initial design utilized welded protrusions. However, during product testing, poor weld sealing integrity caused failures. Compounding the problem, the high cost of the welding process made their component signIficantly more expensive than competitors’. With project deadlines looming, the client was under immense pressure to resolve both quality and co St challenges.

Our Rapid Response & Initial Solution:

Upon learning of the client’s dilemma, we imMediately formed a dedicated technical task force. In the initial technical review, we thoroughly analyzed the root cause of the sealing failure. Through extensive welding parameter optimization trials and the strategic implementation of roboticWelding, we successfully achieved the required sealing integrity, meeting the client’s quality speci Fications.

Identifying the Deeper Issue & Proposing Innovation:

While the immediate sealing issue was resolved, the fundamental problem of prohibitive manufacturing Costs remained. Refusing to settle, our task force engaged in intensive internal brainstorming and maintained close Communication with the client. We proposed a transformative solution: replace the welded assembly with a single-piece component foRmed by stamping and deep drawing.This approach promised to:

- Eliminate the root cause of sealing failures inherent in welding.

- Achieve significant cost reduction By streamlining production.

- EnHance market competitiveness** for the client’s end product.

Breaking Through the “Impossible”:

The client revealed they had previously explored stamping, but other suppliers deemed it unfeasible For this part. Guided by our belief that”Proof lies in practice,” we leveraged our technical expertise to propose crucial design optimizati Ons:

- 1Adjusting the draw angle to improve material flow.

- 2Specifying a higher-grade cold-rolled steel with superior deep-drawing properties.

The Successful Outcome:

After rigorous prototyping and validation testing based on our optimizeD design, we delivered the final component. The results were exceptional, perfectly aligning with the client’s design intent and performance req Uirements.The client expressed deep satisfaction, offering high praise: “This is the perfect product I en Visioned in my design!” They explicitly thanked ChuangKai for solving their persistent technical headache. We enabled the client to meet their critical deadLine while simultaneously overcoming both the quality defect and the cost barrier, significantly enh AnCing their products’s market competitiveness.

Case Study on Improvements for Agricultural Machinery Shaft Breakage

In July 2024, a customer gave feedback that Theirs The axis of the combine harvester There was a rupture during the field operation, and the end customers were very anxious about the fact that the ripe grain could not be harvested smoothly. They initially thought that it might be the raw material of the shaft 40CrNiMoA or the heat treatment process that did not meet the requirements. We have received Their help the broken axis was analyzed at the first time, and it was concluded that it was not Raw materials and There is a problem with the process, but it is designed by the customer.SeasonIt is not taken into account the complex working conditions of the equipment.And one-way force fatigue Hidden dangers, customer requirements Whole Tall Hard Degree heat treatment leads to the high hardness of the core, which is easy to produce Tired Break,After analysis We suggest adopting Whole Adjust the quality plus Surface The process of induction quenching replaces the original heat treatment Overall high hardness The process makes the core Hardness Reduce And the outer surface hardness is high, which meets the wear resistance., and sent it to the customer according to the suggested process.The new sample achieved excellence in the second field experiment.Bear fruit The feedback of.

Power supply box enclosure improvement process

A German customer of our company has a combination box that has difficulty in the design stage. If the riveting method is adopted, it will protrude from the plane to affect the function. If the welding method is used, the appearance does not meet the requirements and the cost is high. After contacting us, we happened to have successful cases in other projects. We can solve customer problems very well by using double flat head rivets and salad holes. We sent samples to customers.

They were very satisfied and achieved rich results at the Hanover exhibition.,AchieveUnanimous praise!

Your End-to-End Manufacturing Solution Partner

Your End-to-End Manufacturing Solution Partner

From Concept to Completion – Precision Engineered for Global Success

At ChuangKai, we eliminate the complexities of multi-vendor sourcing. As a vertically integrated manufacturer specializing in ODM & OEM solutions, we deliver seamless production of high-precision components through our comprehensive capabilities:

Integrated Manufacturing Services:

- Machining: CNC Milling/Turning, Swiss Machining

- Metal Fabrication:Laser Cutting, Bending, Welding

- Stamping & Forming: Progressive Die Stamping, Deep Drawing

- Tooling & Molding:Custom Die/Mold Design & Manufacturing

- Surface Treatment: Powder Coating, Spray Painting

- Assembly & Testing:Full Kitting, Quality Validation

ODM/OEM Advantages for Your Business:

Design Innovation

Our engineering team collaborates with you to optimize designs for manufacturability, cost-efficiency, and performance – transforming concepts into market-ready products.

Single-Source Accountability

No more coordinating 5+ suppliers. We manage the entire workflow under one roof:

Design → Prototyping → Tooling → Raw Material Sourcing → Production → Finishing → Assembly → Logistics

Cost-Smart Production

Vertical integration + process optimization = 15-30% cost reduction vs. fragmented supply chains.

| Speed-to-Market |

Concurrent engineering cuts lead times by 40%. Meet deadlines without compromising quality.

| Quality Built-In |

ISO-certified processes with digital traceability. PPAP, FAIR, and CPK reporting available.

√ Industries We Serve:

Automotive | Industrial Machinery | Medical Devices | Renewable Energy | Robotics | nuclear electricity generation

Why Global Clients Choose Us:

Problem Solvers:Like the [Teaching Demonstration Equipment Case] where we replaced welded assemblies with integrated stamped parts –solving leaks + cutting costs 25%.

Scalable Capacity:Support from NPI prototypes to 1M+ unit production runs.

Technical Agility: 20+ engineers ready to tackle complex GD&T, tight-tolerance (±0.01mm), and material challenges.

→ Request a Free DFM Analysis

Upload your drawings/samples. Our engineers will identify cost & efficiency optimizations within 48 hours.

Products

machine manufacturing

machine manufacturing

FAQ

This section answers common questions about our mechanical and electrical products, services, and policies. It helps you quickly find information without contacting support

Our core strength lies in integrating the entire industrial chain, from precision machining, precision sheet metal processing, stamping production, tolling design and manufacturing, professional surface treatment by spraying to final product assembly, and implementing an outstanding quality management system throughout the entire process. This means that customers do not need to coordinate multiple suppliers to obtain efficient, coordinated, and consistent services. Our strict quality control is implemented in every link, ensuring that what is ultimately delivered is not only parts or products that meet requirements, but also stable, reliable, and high-standard overall solutions, effectively helping customers shorten delivery times, reduce costs, and improve supply chain efficiency.

Customized non-standard component processing. This depends on the complexity of the product. The general delivery period is usually between 2 and 4 weeks.

25

Years Experience

Contact us

recent blog articles

recent articles

Need mechanical and electrical solutions or have questions? Get in touch!

Advantages of precision stamping

30

June

Precision stamping components offer the following advantages: (1) Easy control and high production efficiency. These components are typically manufactured using stamping tooling and specialized equipment, making automated production straightforward. (2) The use of molds during manufacturing ensures dimensional consistency across products. (3) Modern precision metal stamping technology can produce diverse components, even those with complex designs, demonstrating broad applicability across industries.(4) Precision metal stamping parts generally produce minimal scrap during production, enabling efficient material utilization and resulting in relatively low manufacturing costs.

The manufacturing process involves operations such as blanking, bending, deep drawing, forming, and casting-rolling. The raw materials typically consist of hot-rolled or cold-rolled metal sheets (primarily cold-rolled), including carbon steel plates, alloy steel plates, spring steel plates, galvanized sheets, tin-plated sheets, stainless steel sheets, copper and copper alloy sheets, aluminum and aluminum alloy sheets. The hardness testing of stamping materials primarily evaluates whether the purchased metal sheets’ quenching levels are suitable for subsequent stamping processes. Different types of stamping operations require the use of steel plates with corresponding strength grades.

Precision stamping components are manufactured using high-precision toolings through single-station clamping and positioning in the punching process. Given the stringent dimensional accuracy and positional tolerance requirements for workpieces on stamping machines, rigorous finishing processes including die sharpening, heat treatment, surface treatment, and assembly are essential. As these parts are typically produced in small batches or as discrete components, the machinery requirements are relatively modest. During stamping, material flows into the die cavity through gaps in the tooling or mold, where pressure-induced separation or plastic deformation forms the desired shape and structure. After pressure release and controlled process management, the finished product is obtained. This demonstrates that stamping technology represents a classic example of cold forming techniques.

In the production process, to ensure product quality and efficiency while reducing waste and conserving energy, the following practical measures should be implemented: 1. Proper tool selection. 2. Rational choice of raw materials. 3. Establishment of standardized production protocols. 4. Continuous technical training for operators. 5. Enhancement of machine automation. 6. Optimization of working conditions.

The manufacturing characteristics of stamped parts:(1) the utilization rate of materials is high.(2) it can be used to make complex products from relatively thin sheets.(3) it can be made into various structures containing structural columns.

Investigation on the causes and improvement of deformation in precision machining

30

June

The precision mechanical processing performance is not only vital to corporate interests but also safety-critical. While generating economic benefits, it significantly reduces workplace accident risks. Therefore, preventing component deformation during manufacturing is paramount. Operators must consider all relevant factors and implement preventive measures to ensure product integrity. To achieve this, analyzing deformation causes in machining processes and developing reliable countermeasures are essential. These efforts will establish a solid foundation for realizing modern enterprise development strategies.

- Analysis of the causes of deformation in precision machining

- The internal force causes the change of machining accuracy of parts

In lathe machining, the cohesive force principle is typically applied. By using the lathe’s three-jaw or four-jaw chuck to securely hold workpieces, precision mechanical processing can be performed. To ensure parts remain clamped under force and minimize internal axial stress, the clamping force must exceed the mechanical cutting force. The clamping force increases proportionally with the cutting force and decreases accordingly. This operational approach ensures stable force distribution during machining. However, when the three-jaw or four-jaw chuck is released, the machined parts often deviate significantly from the original design—some exhibit polygonal shapes, others become oval, resulting in substantial dimensional deviations.

- It is easy to produce deformation after heat treatment

Sheet metal components, characterized by their large aspect ratio, are prone to developing “hat-shaped bending” after heat treatment. This deformation manifests in two primary ways: first, midsection bulging that amplifies surface flatness deviations; second, bending induced by external environmental factors. These deformation issues arise not only from altered internal stresses post-heat treatment but also stem from operators’ insufficient expertise in component structural stability, which significantly increases deformation risks.

- Elastic deformation caused by external force

There are four primary causes of elastic deformation in mechanical processing. First, components containing internal thin plates require more precise machining techniques. When workers fail to align these components with design drawings during positioning and clamping, elastic deformation often occurs. Second, uneven surfaces on lathes and fixtures create uneven stress distribution during clamping, causing the weaker side to deform under force during cutting. Third, improper positioning during machining reduces component stiffness. Fourth, cutting forces themselves contribute to elastic deformation. These multiple factors collectively demonstrate how external forces significantly impact machining quality.