Use Stretching process Substitute for Weld+Polish +Scrape putty Technology

Break through the technical bottleneck and create high-quality and price-price metal structural parts for teaching demonstration equipment:

When a customer was developing a large demonstration computer for training and teaching, its core metal structural parts encountered serious challenges. The initial design of the part uses the welding process to make the protruding part, but in the product testing stage, the poor welding tightness makes the product unable to pass the key test. At the same time, the high cost of the welding process makes the price of the parts significantly higher than that of competitors, the project delivery is imminent, and customers face great pressure of quality and cost.

Accurately locate pain points and respond quickly to tackle them:

After understanding the customer’s plight, we quickly set up a special technical team. In the first technical seminar, we deeply analyzed the root cause of poor welding airtightness. Although by optimizing welding parameters and introducing welding machinesPeople, we have successfully solved the problem of airtightness and met the initial quality requirements of customers, but the problem of high welding cost is still pending.

Innovative plan, two-proged:

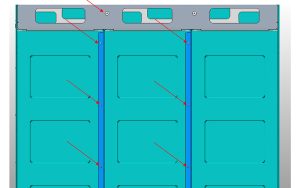

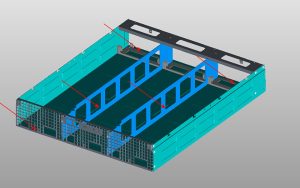

The technical team didn’t stop there. After many rounds of internal discussion and close communication with customers, we have proposed a fundamental solution: replace the original welding with an integrated stamping and stretching process.+Polish+Scrape putty Craft. This not only completely eliminates the risk of welding tightness from the source, but also significantly reduces the production cost and provides the possibility for the product to win a larger market space.

Seize”Impossible”, fulfill the promise:

Customer feedback has considered stamping.StretchingThe plan, but other suppliers said it could not be realized. In the face of questioning, we firmly believe that”One learns by doing”. Based on the profound accumulation of technology, we provide customers with key optimization suggestions, including:

Adjust the tensile slope angle to optimize the material fluidity, and choose a specific brand of cold-rolled steel plate with better tensile performance.

Excellent results, praised by customers:

After the plan was determined, we conducted multiple rounds of rigorous process tests and sample verification. The final delivered parts perfectly meet the customer’s design requirements and performance standards. The customer was extremely satisfied with the results, and not only gave high praise:”This is the perfect product in my ideal design!”He also expressed his sincere thanks for the ability of the Chuangkai team to overcome difficult problems. We have successfully helped customers within the urgent delivery period, while solving difficult quality and cost problems, and helping their products gain an advantage in market competition.

OvercomiNg Technical Hurdles to Deliver High-Quality, Cost-Effective Metal Components for Educational Displa And Systems

The challenge:

A client developing large demonstration computers for training and education faced Critical iss Ues with a key metal structural component. The initial design utilized welded protrusions. However, during product testing, poor weld sealing integrity caused failures. Compounding the problem, the high cost of the welding process made their component signIficantly more expensive than competitors’. With project deadlines looming, the client was under immense pressure to resolve both quality and co St challenges.

Our Rapid Response & Initial Solution:

Upon learning of the client’s dilemma, we imMediately formed a dedicated technical task force. In the initial technical review, we thoroughly analyzed the root cause of the sealing failure. Through extensive welding parameter optimization trials and the strategic implementation of roboticWelding, we successfully achieved the required sealing integrity, meeting the client’s quality speci Fications.

Identifying the Deeper Issue & Proposing Innovation:

While the immediate sealing issue was resolved, the fundamental problem of prohibitive manufacturing Costs remained. Refusing to settle, our task force engaged in intensive internal brainstorming and maintained close Communication with the client. We proposed a transformative solution: replace the welded assembly with a single-piece component foRmed by stamping and deep drawing.This approach promised to:

- Eliminate the root cause of sealing failures inherent in welding.

- Achieve significant cost reduction By streamlining production.

- EnHance market competitiveness** for the client’s end product.

Breaking Through the “Impossible”:

The client revealed they had previously explored stamping, but other suppliers deemed it unfeasible For this part. Guided by our belief that”Proof lies in practice,” we leveraged our technical expertise to propose crucial design optimizati Ons:

- 1Adjusting the draw angle to improve material flow.

- 2Specifying a higher-grade cold-rolled steel with superior deep-drawing properties.

The Successful Outcome:

After rigorous prototyping and validation testing based on our optimizeD design, we delivered the final component. The results were exceptional, perfectly aligning with the client’s design intent and performance req Uirements.The client expressed deep satisfaction, offering high praise: “This is the perfect product I en Visioned in my design!” They explicitly thanked ChuangKai for solving their persistent technical headache. We enabled the client to meet their critical deadLine while simultaneously overcoming both the quality defect and the cost barrier, significantly enh AnCing their products’s market competitiveness.