Advantages of precision stamping

30

June

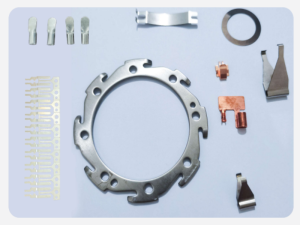

Precision stamping components offer the following advantages: (1) Easy control and high production efficiency. These components are typically manufactured using stamping tooling and specialized equipment, making automated production straightforward. (2) The use of molds during manufacturing ensures dimensional consistency across products. (3) Modern precision metal stamping technology can produce diverse components, even those with complex designs, demonstrating broad applicability across industries.(4) Precision metal stamping parts generally produce minimal scrap during production, enabling efficient material utilization and resulting in relatively low manufacturing costs.

The manufacturing process involves operations such as blanking, bending, deep drawing, forming, and casting-rolling. The raw materials typically consist of hot-rolled or cold-rolled metal sheets (primarily cold-rolled), including carbon steel plates, alloy steel plates, spring steel plates, galvanized sheets, tin-plated sheets, stainless steel sheets, copper and copper alloy sheets, aluminum and aluminum alloy sheets. The hardness testing of stamping materials primarily evaluates whether the purchased metal sheets’ quenching levels are suitable for subsequent stamping processes. Different types of stamping operations require the use of steel plates with corresponding strength grades.

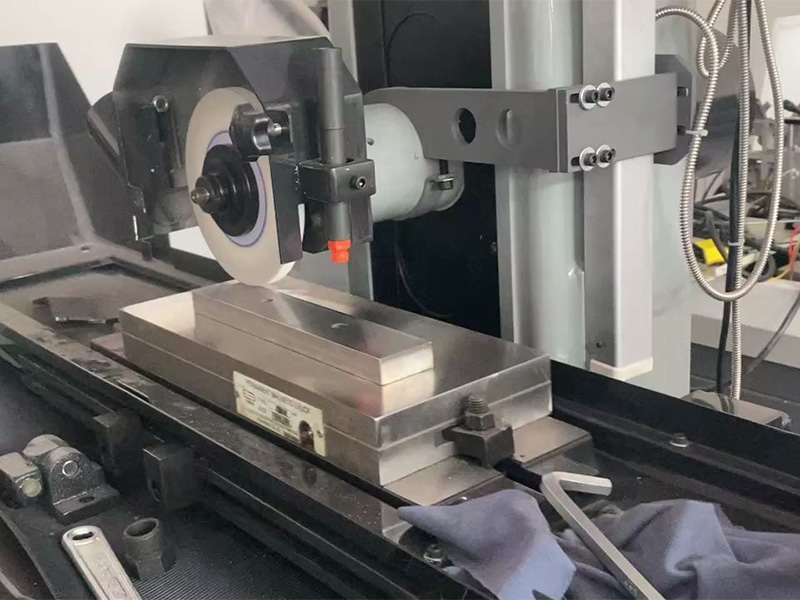

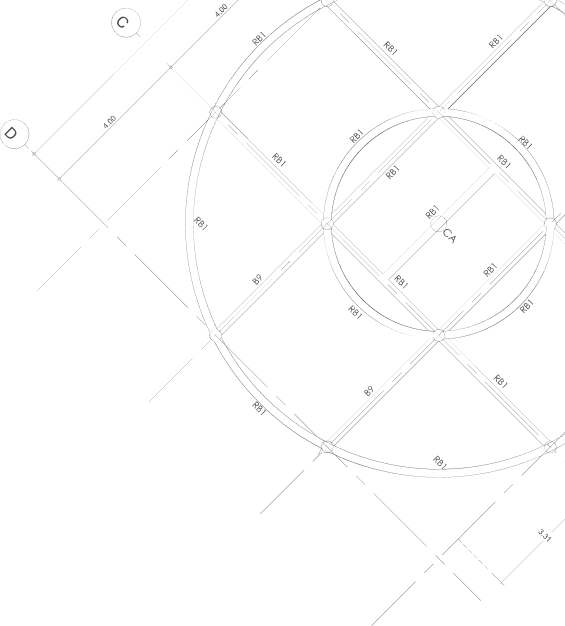

Precision stamping components are manufactured using high-precision toolings through single-station clamping and positioning in the punching process. Given the stringent dimensional accuracy and positional tolerance requirements for workpieces on stamping machines, rigorous finishing processes including die sharpening, heat treatment, surface treatment, and assembly are essential. As these parts are typically produced in small batches or as discrete components, the machinery requirements are relatively modest. During stamping, material flows into the die cavity through gaps in the tooling or mold, where pressure-induced separation or plastic deformation forms the desired shape and structure. After pressure release and controlled process management, the finished product is obtained. This demonstrates that stamping technology represents a classic example of cold forming techniques.

In the production process, to ensure product quality and efficiency while reducing waste and conserving energy, the following practical measures should be implemented: 1. Proper tool selection. 2. Rational choice of raw materials. 3. Establishment of standardized production protocols. 4. Continuous technical training for operators. 5. Enhancement of machine automation. 6. Optimization of working conditions.

The manufacturing characteristics of stamped parts:(1) the utilization rate of materials is high.(2) it can be used to make complex products from relatively thin sheets.(3) it can be made into various structures containing structural columns.