This section answers common questions about our mechanical and electrical products, services, and policies. It helps you quickly find information without contacting support

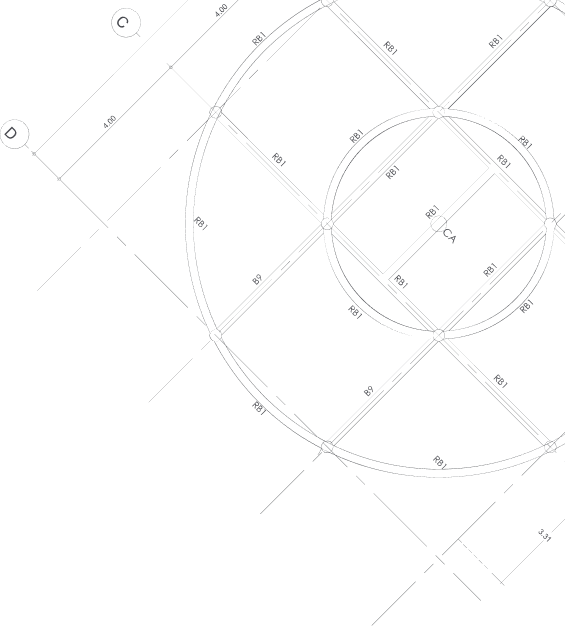

Precision stamping tooling design & manufacture

Main stamping equipment in the stamping workshop: 13 sets of high-speed precision punch presses with specifications such as 16 tons, 25 tons, 40 tons, 60 tons, 80 tons, 110 tons, and 200 tons. The speed of the precision high-speed punch press can reach 500 times per minute.

Materials for stamping processing: brass, phosphor bronze, beryllium bronze, nickel white copper, as well as various types of steel and stainless steel materials, Ni strips, cold-rolled steel, strip steel (including pre-plated), galvanized sheets, low-carbon steel, spring steel, and other composite materials.

Precision sheet metal manufacture

The sheet metal workshop is equipped with precision sheet metal processing equipment, including 2 large-scale advanced CNC laser cutting machines, 1 CNC punch press, 5 CNC bending machines, as well as riveting machines, welding machines, grinders, wire drawing machines and other equipment.

The processed products cover industrial automation, medical equipment, electrical equipment, electrical boxes, electrical junction boxes and other fields. It can perform precision processing such as rapid cutting and sheet metal processing on the following metal materials: stainless steel, carbon steel, silicon steel, aluminum alloy, galvanized sheet, aluminum-zinc plated sheet, etc.

Powder Coating & Painting

One automatic powder coating line;

One manual powder coating line (for large parts and large boxes);

One manual painting line (for large parts and large boxes);

One automatic powder coating and painting hybrid line under construction.

Precision machining

The machining workshop is equipped with precision equipment, including 6 sets of 4-axis CNC machines, 1 set of 5-axis swiss-type lathe, 13 sets of precision CNC lathes, 4 sets of CNC milling machines, 16 sets of Taiwan Mingyang precision automatic lathes, as well as precision ordinary lathes, precision 3-axis digital display milling machines, precision bench lathes, Taiwan Jizuan automatic edge milling machines, precision thread rolling machines, thread rolling dies, precision tapping machines, precision drilling machines, precision Taiwan digital display milling machines, precision knife grinders, internal and external cylindrical grinders, centerless grinders, sawing machines, ultrasonic cleaning and drying machines, polishing machines, electric welders, arc welders and other equipment.

FAQ

Our core strength lies in integrating the entire industrial chain, from precision machining, precision sheet metal processing, stamping production, tolling design and manufacturing, professional surface treatment by spraying to final product assembly, and implementing an outstanding quality management system throughout the entire process. This means that customers do not need to coordinate multiple suppliers to obtain efficient, coordinated, and consistent services. Our strict quality control is implemented in every link, ensuring that what is ultimately delivered is not only parts or products that meet requirements, but also stable, reliable, and high-standard overall solutions, effectively helping customers shorten delivery times, reduce costs, and improve supply chain efficiency.

Customized non-standard component processing. This depends on the complexity of the product. The general delivery period is usually between 2 and 4 weeks.